Product Description

Product Description

Coupling Deatails

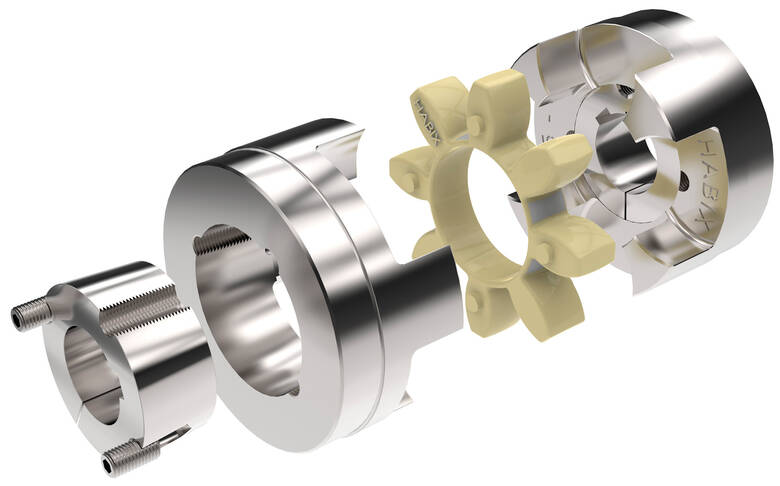

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-04-29

China Custom CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Backlash in Elastic Couplings

Backlash refers to the amount of play or clearance between mating components in a mechanical system, particularly in elastic couplings. In an elastic coupling, backlash is the angular movement or rotation that occurs when there is a change in direction of the input shaft without an immediate response from the output shaft.

Backlash is a result of the elasticity and flexibility of the coupling’s components, such as the elastomer or other flexible elements. When the input direction changes, the elastic elements need to overcome their deformation before transmitting torque to the output shaft. This delay can lead to a temporary loss of motion and reduced precision in positioning applications.

Backlash can have a negative impact on the accuracy, repeatability, and overall performance of a machinery system. It can result in positioning errors, reduced responsiveness, and even potential damage to the system. Therefore, minimizing backlash is crucial in applications that require high precision and responsiveness.

Engineers can address backlash in elastic couplings by selecting couplings with lower compliance, optimizing the design to minimize the flexibility of the coupling elements, and using additional components like anti-backlash devices or preloaded mechanisms.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-04-22

China Standard CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Limitations and Disadvantages of Elastic Couplings

While elastic couplings offer various benefits, they also come with certain limitations and disadvantages that engineers and designers need to consider:

- Torsional Stiffness: Elastic couplings provide flexibility, but this can lead to lower torsional stiffness compared to rigid couplings. In applications requiring high torsional stiffness, elastic couplings might not be the ideal choice.

- Energy Loss: Due to the elastic nature of the material, a portion of the transmitted torque can be absorbed as deformation energy in the elastomer. This can result in energy losses and reduce overall efficiency.

- Wear and Fatigue: The elastomer element in elastic couplings can experience wear, fatigue, and deterioration over time, especially in applications with high loads or extreme operating conditions. Regular maintenance and monitoring are essential to ensure proper functionality.

- Temperature Sensitivity: Some elastomer materials used in elastic couplings might be sensitive to temperature fluctuations. Extreme temperatures can affect the properties of the elastomer and compromise the coupling’s performance.

- Alignment Requirements: While elastic couplings can accommodate minor misalignments, excessive misalignment can still lead to premature wear and reduced coupling lifespan. Proper alignment remains important for optimal performance.

Engineers and designers must carefully assess the specific requirements of their applications to determine if the advantages of elastic couplings outweigh the potential limitations and disadvantages.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Factors to Consider When Selecting an Elastic Coupling

Engineers must carefully evaluate several factors when selecting an appropriate elastic coupling for a specific application. These factors ensure that the coupling can effectively meet the requirements of the machinery and system:

- Torque Transmission: Consider the amount of torque that needs to be transmitted between the connected shafts. Ensure that the coupling’s torque rating matches or exceeds the application’s torque requirements.

- Misalignment Compensation: Evaluate the expected misalignments between the shafts, such as angular, parallel, and axial misalignments. Choose a coupling with the appropriate flexibility and misalignment capacity to accommodate these variations.

- Vibration Dampening: Determine the level of vibration present in the system and select a coupling with the necessary torsional elasticity to dampen vibrations and provide smoother operation.

- Operating Speed: Consider the rotational speed of the connected shafts. Some elastic couplings may have speed limitations, so choose a coupling that can handle the desired operating speed without issues.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, and the presence of contaminants. Choose a coupling material that can withstand the conditions and resist corrosion or degradation.

- Space Limitations: Take into account the available space for installing the coupling. Some couplings may have compact designs that are better suited for confined spaces.

- Shaft Sizes: Ensure that the coupling is compatible with the diameters of the connected shafts. Verify the coupling’s bore sizes and choose one that matches the shaft sizes.

- Installation and Maintenance: Consider the ease of installation and maintenance. Some couplings have simpler installation procedures, while others might require more complex procedures.

- Cost: Evaluate the budget for the coupling. While high-performance couplings might have added benefits, they could also come at a higher cost. Balance the performance requirements with budget constraints.

By carefully assessing these factors and selecting the appropriate elastic coupling, engineers can ensure optimal performance, longevity, and reliability of the machinery and systems they design.

editor by CX 2024-04-13

China Standard CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Types of Elastic Couplings for Specific Applications

There are various types of elastic couplings available, each designed to suit specific industrial applications:

- Flexible Jaw Couplings: These couplings use an elastomeric element to transmit torque and accommodate misalignment. They are commonly used in applications where shock absorption and vibration damping are important, such as pumps, compressors, and conveyor systems.

- Diaphragm Couplings: Diaphragm couplings use thin metal diaphragms to transmit torque while allowing for angular, axial, and radial misalignment. They are often used in high-performance applications where precise motion transmission is required, such as in robotics, precision machinery, and aerospace systems.

- Torsional Couplings: Torsional couplings are designed to handle high torque loads and are commonly used in heavy-duty applications, including industrial machinery, mining equipment, and large pumps.

- Disc Couplings: Disc couplings use multiple thin metal discs to transmit torque and accommodate misalignment. They are suitable for applications requiring high torque transmission and precise motion control, such as turbines, generators, and high-speed machinery.

- Beam Couplings: Beam couplings use helical cuts in a flexible beam to provide torsional flexibility and misalignment compensation. They are used in applications that require moderate torque transmission and misalignment accommodation, such as stepper motors and motion control systems.

- Oldham Couplings: Oldham couplings use three disks to transmit torque while allowing for axial misalignment. They are commonly used in applications that require accurate motion transmission, such as linear actuators and CNC machinery.

The choice of the right type of elastic coupling depends on factors such as the application’s torque requirements, speed, misalignment characteristics, and specific performance needs.

editor by CX 2024-04-03

China Custom CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Material Selection and Design Durability of Elastic Couplings

The choice of materials for elastic couplings significantly influences their design and overall durability. Material selection affects factors such as flexibility, torsional stiffness, fatigue resistance, and resistance to environmental conditions. Here’s how material selection plays a crucial role:

- Elastomer Material: The elastomer used in elastic couplings determines the coupling’s flexibility, vibration absorption capabilities, and resilience. Common elastomers include natural rubber, synthetic rubber, and polyurethane. The selected elastomer should provide the desired level of elasticity and durability while maintaining its properties over time.

- Hub and Spacer Material: The hubs and spacers of elastic couplings are typically made from metals like steel, aluminum, or alloy materials. These components need to be strong enough to transmit torque while accommodating misalignments and vibrations. The material should also resist wear, corrosion, and fatigue.

- Bolt or Pin Material: Bolts or pins used to connect the hubs and elastomer element must possess sufficient strength to handle the torsional forces and loads. They should be made from materials with high tensile strength and corrosion resistance.

- Environmental Factors: Depending on the application environment, material selection should consider factors such as temperature, moisture, chemicals, and UV exposure. The chosen materials should be able to withstand these conditions without deterioration.

Ultimately, a well-considered material selection enhances the coupling’s durability, operational performance, and resistance to wear, ensuring that the elastic coupling can reliably function under varying conditions and loads.

Impact of Temperature Variations on Elastic Coupling Performance

Elastic couplings can be sensitive to temperature variations, and their performance can be influenced by both high and low temperatures:

1. High Temperatures: Elevated temperatures can cause the elastomeric material used in elastic couplings to soften, leading to a decrease in its mechanical properties. This can result in reduced torsional stiffness, damping capabilities, and overall coupling performance. High temperatures can also accelerate the aging process of the elastomer, leading to a shorter lifespan of the coupling. Additionally, excessive heat can cause thermal expansion of the coupling’s components, potentially leading to misalignment issues.

2. Low Temperatures: Extremely low temperatures can cause the elastomeric material to become more rigid, reducing its flexibility and damping characteristics. This can result in increased transmission of vibrations and shocks between connected components. Cold temperatures can also make the elastomer more brittle, increasing the risk of cracking or rupturing under mechanical stress.

It’s important to select an elastic coupling material that is suitable for the anticipated temperature range of the application. Some elastomers are formulated to perform well across a wide temperature range, while others are better suited for specific temperature conditions. Regular maintenance and inspection of elastic couplings in extreme temperature environments are crucial to ensure that the coupling continues to function as intended.

Difference Between Elastic Coupling and Rigid Coupling

Elastic couplings and rigid couplings are two distinct types of couplings used in mechanical designs:

Elastic Coupling: An elastic coupling incorporates an elastomeric material, such as rubber, to provide flexibility and absorb shock and vibration. It allows for misalignment compensation and is ideal for applications where there may be slight misalignment or the need for vibration damping. Elastic couplings are commonly used in machinery that requires smooth operation and reduced stress on connected components.

Rigid Coupling: A rigid coupling, as the name suggests, is designed to provide a solid connection between two shafts. It does not have any flexible or damping elements and is used when precise alignment and torque transmission are critical. Rigid couplings are often used in applications where shafts need to maintain a constant alignment, such as in precision machines and systems with high torque requirements.

The choice between an elastic coupling and a rigid coupling depends on the specific requirements of the mechanical system, including the degree of misalignment, vibration levels, torque transmission, and the overall performance objectives.

editor by CX 2024-04-03

China Clamp type curved jaw coupling TS2C-40-20-22 Aluminum Alloy High precision flexible shaft connector Factory Price servo motor cast of coupling

Guarantee: 1 yr

Applicable Industries: Garment Retailers, Developing Materials Retailers, Production Plant, Equipment Repair Shops, Clamp electrical power locks High High quality keyless shaft-hub locking gadget adjustable defense Company industrial tools Foodstuff & Beverage Manufacturing unit, Farms, Energy & Mining, Other

Tailored support: OEM

Construction: Jaw / Spider

Flexible or Rigid: Versatile

Common or Nonstandard: Common

Material: Aluminium

Merchandise identify: Clamp kind curved jaw coupling

Type: TS2C-40-20-22

Physique Material: Aluminum Alloy

Software: Shaft Connections

Measurement: Normal Size

Coloration: Metal Shade

MOQ: 1 Set

Support: twelve Months

Top quality: 100%analyzed

Shaft measurement(mm): 20mm

Packaging Particulars: normal export packing and wooden pallets packing

Port: ZheJiang port, forty five# steel materials Versatile Coupling HTLA Jaw Spider Coupling China

Sizzling Sale

| 1. Product Identify | Clamp kind curved jaw coupling |

| two. Type | TS2C-forty-20-22 |

| three. Software | Shaft Connection |

| 4. Brand | HangZhou Tanso |

| five. MOQ | 1 Set |

| 6. Cost | EXW price tag |

| seven. Shipping and delivery Way | By sea, DHL, UPS, Fedex or as customers’ China provider CGM5503 tyre coupling for machinery demands |

| eight. Payment Phrases | By means of T/T |

| nine. Delivery Time | In 15-20 workdays soon after deposit or as customers’ need |

| ten. Packaging | one. Export Wood Box two. Carton Box three. We can perform according to customers’ needs |

Certifications

Business Information

Packaging & Delivery

Programs

FAQ

What Is a Coupling?

A coupling is a mechanical device that links two shafts together and transmits power. Its purpose is to join rotating equipment while permitting a small amount of misalignment or end movement. Couplings come in a variety of different types and are used in a variety of applications. They can be used in hydraulics, pneumatics, and many other industries.

Types

Coupling is a term used to describe a relationship between different modules. When a module depends on another, it can have different types of coupling. Common coupling occurs when modules share certain overall constraints. When this type of coupling occurs, any changes to the common constraint will also affect the other modules. Common coupling has its advantages and disadvantages. It is difficult to maintain and provides less control over the modules than other types of coupling.

There are many types of coupling, including meshing tooth couplings, pin and bush couplings, and spline couplings. It is important to choose the right coupling type for your specific application to get maximum uptime and long-term reliability. Listed below are the differences between these coupling types.

Rigid couplings have no flexibility, and require good alignment of the shafts and support bearings. They are often used in applications where high torque is required, such as in push-pull machines. These couplings are also useful in applications where the shafts are firmly attached to one another.

Another type of coupling is the split muff coupling. This type is made of cast iron and has two threaded holes. The coupling halves are attached with bolts or studs.

Applications

The coupling function is an incredibly versatile mathematical tool that can be used in many different scientific domains. These applications range from physics and mathematics to biology, chemistry, cardio-respiratory physiology, climate science, and electrical engineering. The coupling function can also help to predict the transition from one state to another, as well as describing the functional contributions of subsystems in the system. In some cases, it can even be used to reveal the mechanisms that underlie the functionality of interactions.

The coupling selection process begins with considering the intended use of the coupling. The application parameters must be determined, as well as the operating conditions. For example, if the coupling is required to be used for power transmission, the design engineer should consider how easily the coupling can be installed and serviced. This step is vital because improper installation can result in a more severe misalignment than is specified. Additionally, the coupling must be inspected regularly to ensure that the design parameters remain consistent and that no detrimental factors develop.

Choosing the right coupling for your application is an important process, but it need not be difficult. To find the right coupling, you must consider the type of machine and environment, as well as the torque, rpm, and inertia of the system. By answering these questions, you will be able to select the best coupling for your specific application.

Problems

A coupling is a device that connects two rotating shafts to transfer torque and rotary motion. To achieve optimal performance, a coupling must be designed for the application requirements it serves. These requirements include service, environmental, and use parameters. Otherwise, it can prematurely fail, causing inconvenience and financial loss.

In order to prevent premature failure, couplings should be properly installed and maintained. A good practice is to refer to the specifications provided by the manufacturer. Moreover, it is important to perform periodic tests to evaluate the effectiveness of the coupling. The testing of couplings should be performed by qualified personnel.

editor by czh 2023-03-16

China Factory Price cnc Flexible mp type aluminum shaft double disc coupling Custom OEM Logo Minow coupling base

Relevant Industries: Production Plant, Machinery Mend Stores, Other

Custom-made assist: OEM, OBM

Composition: diaphragm

Versatile or Rigid: Flexible

Standard or Nonstandard: Nonstandard

Content: aluminium alloy

MOQ: ten

Entire body Content: Aluminum Alloy

Variety: MP2-34

Packing: Carton Box

Exterior Diameter(D): 34

Duration: forty five

Packaging Specifics: First pack cartons then set them in picket instances

Port: ZheJiang port,HangZhou Port

Products Description Organization Profile HangZhou Minow Transmission Equipment Co.,Ltd. Was founded in 2005,it is found in HangZhou metropolis,ZHangZhoug Province,China. Our firm specializes in the investigation,manufactrure and income of automated coupling,synchronous belt pulley,expansion sleeve, Automated Gearbox Stress Meter Package Transmission Fluid Diagnostic Tester Tool Package With Hose and Adapters motor seat,bearing seat,servo motor,gearbox,equipment and drive shaft and other engineering equipment and agricultural equipment elements. Goods are commonly usd in CNC device resources,machining facilities,injection molding machinery,textile equipment,maedical equipment,agricultural equipment,engineering equipment production and other fields. Our company introduces innovative turning milling compound heart, machining centre,CNC lathe, Custom made little steel nylon plastic super gear hobbing and grinding equipment,and other high-precision gear to ensure that each merchandise to obtain substantial precision,lower sound,substantial overall performance and extended life.We adhere to scientific and arduous administration mode and producing approach,in purchase to achieve the have confidence in of consumers.Our products are exported to The united states,Japan,Germany,Russia,Egypt and other international locations. Businesses adhering to the bussiness philosophy of “honest and reliable,groundbreaking and enter prising”,adhere to exceptional merchandise top quality, Powder metallurgy preserve 80% price customized steel metal CZPT pinion wheel small micro bevel differential gears best administration ,concerted attempts,honest provider for the culture and our consumers.

Understanding the Different Types of Couplings

A coupling is a device that joins two rotating shafts together. It transmits power from one to the other and is designed to allow some amount of end-movement and misalignment. It is a simple mechanism that is extremely common in many industries. Learn more about couplings in this article.

Flexible coupling

When choosing the correct flexible coupling for your application, there are several factors to consider. One of the most important factors is backlash, which is the amount of rotational play introduced by moving parts. Other factors to consider include lubrication and accessibility for maintenance. Choosing the right flexible coupling can be challenging, but it is possible to find the right fit for your specific application.

A flexible coupling is an excellent choice for applications that require high alignment accuracy, which is essential for reliable system performance. These couplings can compensate for angular and parallel misalignment, ensuring proper positioning between the driving and driven shafts. In addition, flexible couplings are more affordable than most traditional couplings.

The most common flexible coupling is the elastomeric type, which uses a resilient material to transmit torque. These couplings can be made of plastic or rubber. In either case, they can be relatively lightweight compared to other types of couplings. Elastomeric couplings can also be used for high-speed applications.

Another important factor to consider when selecting the best Flexible Coupling is the pipe you’re connecting. Some couplings are easier to install than others, and some even have tapered edges to make them slide easily on the pipe. Regardless of the choice you make, it’s crucial to remember that proper installation is critical for reliability and safety.

CZPT coupling

An CZPT coupling is a flexible, mechanical coupling that features a high degree of angular misalignment and eccentricity. They are available in different lengths, with MOL being the longest. They are ideal for applications that involve high parallel misalignment, limited assembly access, electrical insulation, and other conditions.

CZPT couplings are a versatile type of coupling, and they are often used to connect parallel shafts. They work by transmitting torque from one to the other using the same speed and rotation mechanism. They are available in various materials, including aluminum, brass, and polymers. In addition, they can work under high temperatures.

One of the main benefits of using an CZPT coupling is the fact that it does not require the use of a gearbox. These couplings are flexible, and their design allows them to cope with misalignment problems that may occur in power transmission applications. They are also able to absorb shock.

Another advantage of CZPT couplings is that they are suitable for systems with low-to-medium amounts of shaft misalignment. Because their friction is limited to the surface of the hubs, they are able to accommodate low bearing loads. CZPT couplings can also be used in systems with limited shaft access, since the disks are easily removed.

Clamped coupling

Clamped couplings are designed to provide a high-strength connection between two objects. A standard coupling has two parts: a nipple and a clamp sleeve. Each part is designed in such a way as to cooperate with each other. The sleeve and clamp are made of rubber. A reinforcing braid is often used to protect the exposed steel braid from rusting.

PIC Design provides a wide variety of standard clamping couplings for many different industries. These include medical, dental, military, laboratory, and precision industrial control equipment. They have a simple design that makes them ideal for these applications. Clamped couplings are also available for custom manufacturing. These couplings are available in metric, inch, and Metric.

The most common type of clamp coupling is a hose clamp. This type of coupling is used to connect two hoses or piping units. It consists of two conical binding sleeves that fit into the ends of the two parts. The coupling is then tightened with a screwdriver. It’s a versatile coupling because it allows two piping units or hoses to be joined together.

Another type of clamp coupling is the two-piece clamp coupling. The two-piece design allows for a quick and easy installation. Unlike other types of couplings, the clamp coupling is not necessary to remove the bearings before installing it. Its keyway is designed with shims in place so that it fits over the shaft. These couplings are available in different sizes, and they are made of steel or dutile iron.

Helicoidal coupling

Helicoidal coupling is a form of nonlinear coupling between two molecules. It occurs when the molecules in a double helix are subjected to oscillations. These oscillations can occur either in the right or left-handed direction. These oscillations are called solitons. Helicoidal coupling can provide quantitative or qualitative support to a structure, such as an electron.

Split Muff coupling

The Split-Muff Coupling market report provides detailed market analysis and key insights. The study covers the market size, segmentation, growth and sales forecast. It also examines key factors driving the market growth and limiting its development. The report also covers current trends and vendor landscapes. Therefore, you can get a deep understanding of the Split-Muff Coupling industry and make the right business decisions.

The report also provides data on the competitive landscape and the latest product and technology innovations. It also provides information on market size, production and income. It also covers the impact of the COVID-19 regulations. The market report is a valuable resource for companies looking to expand their businesses, or to improve existing ones.

In terms of application, Split-Muff Couplings can be used in light to medium duty applications. They are shaped like a semi-cylindrical disc that fits over a shaft. Both parts are threaded for assembly and disassembly. It can be disassembled easily and quickly, and can be used for medium to heavy-duty applications with moderate speeds.

Split Muff couplings are the most popular type of couplings for transferring wet and abrasive materials. Their flanged end fits on most major brands of smooth material muff hoses. In addition, this type of coupling is corrosion-resistant and easy to install. It also does not require any adjustments to the drive shaft’s position.

Flexible beam coupling

The Flexible beam coupling is one of the most popular types of couplings in the industry. It is comprised of two sets of parallel coils separated by a solid member, and it offers a wide range of torsional stiffness. These couplings are made of aluminum alloy or stainless steel. They offer excellent flexibility and are less expensive than many other types of couplings. They also require zero maintenance and can tolerate shaft misalignment.

Beam couplings are categorized into two types: helical and axial. The former is characterized by a high degree of flexibility, while the latter is used to compensate for higher misalignment. Both types are suitable for small torque applications and are available in a wide range of shaft sizes.

Flexible beam couplings are available in metric and US sizes, and feature a variety of options. They feature stainless steel or aluminum materials and are highly durable and corrosion-resistant. They also offer high torque capacities and excellent fatigue resistance. Flexible beam couplings are available with a wide range of options to meet your unique application needs.

editor by czh 2023-03-11

China D20L35 D32L45 Flexible Coupling Aluminum Shaft Couplings Flexible Coupler for 3D Printer coupling assembly

Warranty: 1 a long time

Relevant Industries: Building Content Stores, Production Plant, Equipment Repair Shops, Retail, Printing Outlets, Design works , Advertising and marketing Company

Customized help: OEM

Structure: Common

Adaptable or Rigid: Versatile

Standard or Nonstandard: Regular

Material: Aluminium

Merchandise name: D20L35 D32L45 Adaptable Coupling Aluminum Shaft Couplings

Attribute: Long Working Daily life

Software: Industrial Gear

Type: Versatile Clamp Coupling

Body Material: Aluminum Alloy

Standard: ISO2531

Shaft size: Custermized

Gain: Lower Transmission Effectiveness Reduction

Support: Tailored OEM

Payment: TT Paypal Weston Union

Packaging Particulars: D20L35 D32L45 Flexible Coupling Aluminum Shaft Couplings Flexible Coupler for 3D Printer scenario:1.Sample order be packed by paper carton for saving freight charge2.Bulk buy delivered by sea will be packed by movie and wooden carton3.In accordance to the customer’s specifications

Port: HangZhou, China

D20L35 D32L45 Versatile Coupling Aluminum Shaft Couplings Adaptable Coupler for 3D Printer

| item | Aluminium Plum Versatile Jaw Shaft Coupling |

| Place of Origin | China |

| ZheJiang | |

| Merchandise identify | Shaft Couplings |

| Application | Industrial Gear |

Packaging & DeliveryPackaging and Shipping and delivery :

1.Sample order be packed by paper carton for conserving freight demand

2.Bulk buy shipped by sea will be packed by movie and wood carton

3.According to the customer’s needs

Firm InformationOrganization Information:

Organization tenet:

Strive for excellence, replicate price.

Organization slogan:

Science and engineering creates the foreseeable future.

Enterprise spirit:

Revolutionary and innovation, Spiral Bevel Equipment for Device Tool unity and determination.

Provider philosophy:

Leading technonogy, good quality very first, sincere service, client very first.

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is positioned at Xihu (West Lake) Dis. industrial zone Xihu (West Lake) Dis. County which is the stunning Xihu (West Lake) Dis. Drinking water Town and the popular painting and calligraphy village.The south is countrywide street 308, the west is the countrywide highway one zero five,the north is HangZhou-HangZhou highway, so the situation is extremely outstanding. It is 1 of the greatest linear companies in China.

Customers Browsing and Exhibition

Several buyers have visitd our factory,and they had been happy with our manufacturing unit and goods,and we frequently go to intercontinental Truthful,our merchandise is well-known in the planet, Authentic CVT Gearbox OEM JF011E Transmission for CZPT Sentra Tiida CZPT we have exported a lot more than 70 nations because 2011.

FAQFAQ:

1. Q: How about the quality of your product?

A: 100% inspection during manufacturing.

Our merchandise are qualified to ISO9001-2008 intercontinental top quality expectations.

two. Q: What is actually the shipping and delivery time?

A: For personalized buy, inside 2000 meters,

Production time is 15days soon after confirmed each details.

three. Q: What is your packing?

A: Our Standard packing is bulking in PE bag, and then into plywood Cartons.

We also can pack items according to your necessity.

four. Q: What about the guarantee?

A: We are really assured in our merchandise,

and we pack them very effectively to make positive the goods in well security.

five.Q: Could you send out me your catalogue and price list?

A: As we have more than hundreds of items,

it is actually too challenging to send all of catalogue and cost checklist for you.

Remember to inform us the design you intrigued, we can offer the pricelist for your reference.

six.Q:There are a good deal of companies which export bearings, why do you choose us?

A: As we are a authentic linear guide provider because 2011.and we are really manufacturing unit, you require not pay the income for middlemen. so we can offer you the most affordable and competitive price .

Thanks for your beneficial time ! Manufacturing facility manufacture specialist brass stainless steel cnc machining equipment

Functions and Modifications of Couplings

A coupling is a mechanical device that connects two shafts and transmits power. Its main purpose is to join two rotating pieces of equipment together, and it can also be used to allow some end movement or misalignment. There are many different types of couplings, each serving a specific purpose.

Functions

Functions of coupling are useful tools to study the dynamical interaction of systems. These functions have a wide range of applications, ranging from electrochemical processes to climate processes. The research being conducted on these functions is highly interdisciplinary, and experts from different fields are contributing to this issue. As such, this issue will be of interest to scientists and engineers in many fields, including electrical engineering, physics, and mathematics.

To ensure the proper coupling of data, coupling software must perform many essential functions. These include time interpolation and timing, and data exchange between the appropriate nodes. It should also guarantee that the time step of each model is divisible by the data exchange interval. This will ensure that the data exchange occurs at the proper times.

In addition to transferring power, couplings are also used in machinery. In general, couplings are used to join two rotating pieces. However, they can also have other functions, including compensating for misalignment, dampening axial motion, and absorbing shock. These functions determine the coupling type required.

The coupling strength can also be varied. For example, the strength of the coupling can change from negative to positive. This can affect the mode splitting width. Additionally, coupling strength is affected by fabrication imperfections. The strength of coupling can be controlled with laser non-thermal oxidation and water micro-infiltration, but these methods have limitations and are not reversible. Thus, the precise control of coupling strength remains a major challenge.

Applications

Couplings transmit power from a driver to the driven piece of equipment. The driver can be an electric motor, steam turbine, gearbox, fan, or pump. A coupling is often the weak link in a pump assembly, but replacing it is less expensive than replacing a sheared shaft.

Coupling functions have wide applications, including biomedical and electrical engineering. In this book, we review some of the most important developments and applications of coupling functions in these fields. We also discuss the future of the field and the implications of these discoveries. This is a comprehensive review of recent advances in coupling functions, and will help guide future research.

Adaptable couplings are another type of coupling. They are made up of a male and female spline in a polymeric material. They can be mounted using traditional keys, keyways, or taper bushings. For applications that require reversal, however, keyless couplings are preferable. Consider your process speed, maximum load capacity, and torque when choosing an adaptable coupling.

Coupling reactions are also used to make pharmaceutical products. These chemical reactions usually involve the joining of two chemical species. In most cases, a metal catalyst is used. The Ullmann reaction, for instance, is an important example of a hetero-coupling reaction. This reaction involves an organic halide with an organometallic compound. The result is a compound with the general formula R-M-R. Another important coupling reaction involves the Suzuki coupling, which unites two chemical species.

In engineering, couplings are mechanical devices that connect two shafts. Couplings are important because they enable the power to be transmitted from one end to the other without allowing a shaft to separate during operation. They also reduce maintenance time. Proper selection, installation, and maintenance, will reduce the amount of time needed to repair a coupling.

Maintenance

Maintenance of couplings is an important part of the lifecycle of your equipment. It’s important to ensure proper alignment and lubrication to keep them running smoothly. Inspecting your equipment for signs of wear can help you identify problems before they cause downtime. For instance, improper alignment can lead to uneven wear of the coupling’s hubs and grids. It can also cause the coupling to bind when you rotate the shaft manually. Proper maintenance will extend the life of your coupling.

Couplings should be inspected frequently and thoroughly. Inspections should go beyond alignment checks to identify problems and recommend appropriate repairs or replacements. Proper lubrication is important to protect the coupling from damage and can be easily identified using thermography or vibration analysis. In addition to lubrication, a coupling that lacks lubrication may require gaskets or sealing rings.

Proper maintenance of couplings will extend the life of the coupling by minimizing the likelihood of breakdowns. Proper maintenance will help you save money and time on repairs. A well-maintained coupling can be a valuable asset for your equipment and can increase productivity. By following the recommendations provided by your manufacturer, you can make sure your equipment is operating at peak performance.

Proper alignment and maintenance are critical for flexible couplings. Proper coupling alignment will maximize the life of your equipment. If you have a poorly aligned coupling, it may cause other components to fail. In some cases, this could result in costly downtime and increased costs for the company.

Proper maintenance of couplings should be done regularly to minimize costs and prevent downtime. Performing periodic inspections and lubrication will help you keep your equipment in top working order. In addition to the alignment and lubrication, you should also inspect the inside components for wear and alignment issues. If your coupling’s lubrication is not sufficient, it may lead to hardening and cracking. In addition, it’s possible to develop leaks that could cause damage.

Modifications

The aim of this paper is to investigate the effects of coupling modifications. It shows that such modifications can adversely affect the performance of the coupling mechanism. Moreover, the modifications can be predicted using chemical physics methods. The results presented here are not exhaustive and further research is needed to understand the effects of such coupling modifications.

The modifications to coupling involve nonlinear structural modifications. Four examples of such modifications are presented. Each is illustrated with example applications. Then, the results are verified through experimental and simulated case studies. The proposed methods are applicable to large and complex structures. They are applicable to a variety of engineering systems, including nonlinear systems.

editor by czh 2023-03-04

China Coupling manufacturers supply SG7-8 series double disk flexible coupling aluminum alloy shaft 25mm couplings for servo motor manufacturer

Guarantee: 1 12 months

Applicable Industries: Creating Content Shops, Production Plant, Equipment Restore Stores, Food & Beverage Factory, transparent equipment auto cartoon large G with colorful gentle and tunes walking off-road vehicle children’s toy Retail, Printing Outlets, Power & Mining

Customized support: OEM, ODM, 22mm Luxury Titanium Steel Observe Band For CZPT Gt2 Gt3 3 Pro Business Bracelet For CZPT Galaxy Watch 46mm Gear S3 Strap OBM

Construction: Disc

Flexible or Rigid: Flexible

Regular or Nonstandard: Normal

Materials: Aluminium

Packaging Specifics: picket packing

Port: ZheJiang

FAQ Q: How long is the quality assure?A: One particular yr assure.Q: How prolonged is the delivery time?A: Usually it is 3-7 times if the goods are in stock. If the products are not in stock, it will consider 8-twenty days.Q: Do your merchandise have a manufacturing unit inspection ahead of cargo?A: 1mm spur rack gear and pinion for cnc machine or utilize for other ports.

| Welcome online consultation |

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by czh 2023-02-26

China Aluminum Alloy Shaft Motor Rigid Solid Motor Gg25 Silver 12mm Shaft Coupling coupling distance

Applicable Industries: Lodges, Garment Outlets, Creating Substance Stores, Production Plant, Machinery Mend Outlets, Food & Beverage Manufacturing facility, Farms, Cafe, Home Use, Retail, Foodstuff Store, Printing Retailers, Development works , Power & Mining, Foods & Beverage Retailers, Marketing Business

Structure: Equipment

Adaptable or Rigid: Rigid

Regular or Nonstandard: Standard

Material: Aluminium, Aluminum alloy (6063), Anodizing remedy.

Product: SRB-L22

Fastening Screws: 4*M3

Software: Hardware, mold, mechanical transmission, intelligent vehicle

Dimensions: D14(16) H25mm

Packaging Particulars: 1. Common carton packaging. 2. Use EPS foam or EPE cotton within the carton.

Port: HangZhou

Aluminum Alloy Shaft Motor Rigid Sound Motor Gg25 Silver 12mm Shaft Coupling

| Model | SRIBO |

| Product | SRB-L22 |

| Content | Aluminum alloy (6063), Anodizing therapy. |

| Dimension | D14(16)×H25mm |

| Interior Gap Tolerance | +.05 |

| Fastening Screws | 4×M3 |

| Software | Hardware, mould, mechanical transmission, wise auto |

| Product | SRB-L22 | |||||||||

| Specification | four=four | five=five | five=6 | five=eight | six=six | 6=eight | 6=ten | eight=8 | 8=ten | ten=ten |

| Coupling Hole D1/mm | 4mm | 5mm | 5mm | 5mm | 6mm | 6mm | 6mm | 8mm | 8mm | 10mm |

| Coupling Hole D2/mm | 4mm | 5mm | 6mm | 8mm | 6mm | 8mm | 10mm | 8mm | 10mm | 10mm |

| Coupling outer diametermm | 14mm | 14mm | 14mm | 14mm | 14mm | 14mm | 16mm | 14mm | 16mm | 16mm |

Produts Display

Motor selection meth

SoftwareTypical applications:

one. Home applications: white merchandise, small appliances, fans, electric powered screens, automatic window opening, German technological innovation Wholesale price CZPT model PA180 16a maritime gearbox flooring cleaning robots, vacuum cleaners, smart property techniques.

two. Health-related programs: medical pumps, sphygmomanometers, surgical equipment, medical agitators, centrifuges.

three. Energy resources: air pump, water pump, vacuum pump, oxygen generator, electric powered drill, electrical screwdriver.

4. Business products: printers, copiers, shredders, projectors, scanners, cash registers, vending machines.

five. Private care: hair dryer, electric shaver, elegance item, hair curler, steam hair straightener (h2o jet straight hair outlet).

six. CZPT field: massager, adult toy.

seven. Stability subject: surveillance program, camera, risk-free.

eight. Industrial apps: robotic arms, printing equipment, automation products.

nine. Other applications: electronic door locks, intelligent switches, robots, toys, sensible cars, Customized Forging Alloy Steel 34CrNiMo6 Higher Precision Large Metal Spur Equipment Wheel Girth Gear boats, intelligent put on, electronics, Diy, and so on.

Recognize:

Hello, I am very pleased to see our merchandise. We are professional motor OEM/ODM makers, and have practically eleven years of creation and R&D knowledge. We have our very own factory and technological engineers. We are found in HangZhou, China, If you are interested in our goods, there are any motor customization needs, welcome to speak to us, our expert solutions to answer your queries.

Firm Info

Packaging & Transport

FAQ FAQ

Q1: Are you a Manufacturer or a Trading Firm ?

A:We are a expert maker with over eleven several years of encounter, and have a comprehensive provide chain from components processing to completed goods.

Q2: What’re your principal products ?

A: The main productions are: Brush dc motor, Brushless dc motor, Spur equipment motor, Micro motor, Vibration motor, Turbo worm geared motors, Geared motors with Hall encoders, Planetary geared motors, Micro pump motors, Smart car motor sets, Velocity reducers, Speed controllers, Power adapters, Switches Electricity supply and related motor components. Other kinds of motors, make sure you speak to buyer service for customization.

Q3: How is your High quality Control ?

A: We have skilled checking staff on every creation line method. Soon after ending the complete motor, we have the entire good quality machine to take a look at the motor. Such as Hardness Tester, 2.5D Impression Tester, Linear and Angular Planetary Gearbox Substitution of Reggiana Riduttori RR65 RR105 RR110 RR210 RR310 RR510 RR710 RR810 RR1571 Salt Spray Chamber, Lifestyle Tester, Temperature Check Equipment, and Noise tester and many others.

This autumn: How to buy ?

A: Send Us Inquiry → Receive Our Quotation → Negotiate Particulars → Affirm The Sample → Indicator Agreement/Deposit → Mass Creation →Cargo Prepared → Balance/Shipping → Further Cooperation

Q5: How about Sample get ?A: Sample is accessible for you. remember to make contact with us for specifics. After we charge you sample payment, make sure you come to feel straightforward, it would be refund when you place official purchase.

Q6: How lengthy is the provide[Making] and delivery ?

A: one. Supply time is dependent on the amount you get. generally it will take 15-25 operating times.

2. Normal sort products can be delivered inside 3 doing work times, and other tailored samples can be shipped within 7-ten functioning times.