Product Description

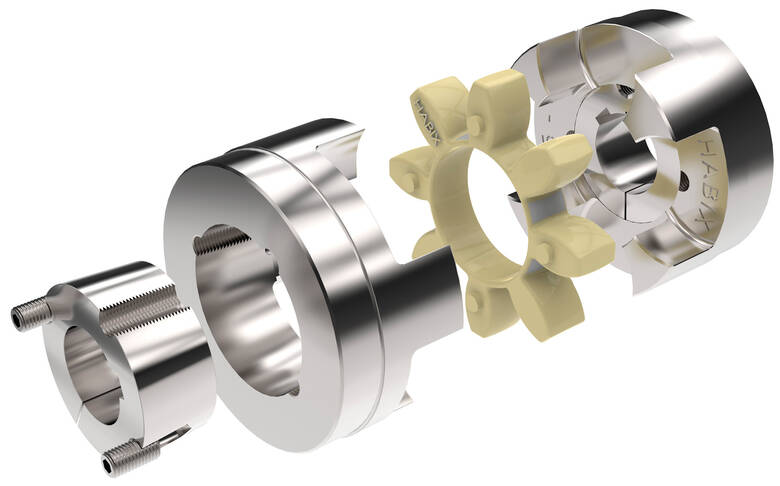

Power transmission flexible plum shaped jaw nylon spider coupling XLD Type elastic coupling

Features:

XLD star-shaped flexible coupling is made of aluminum alloy as bushings and engineering plastic as an elastic element, suitable for connecting the 2 coaxial transmission shaft system.

Similar function as of XL type,but the bore dimension and outer dimension is bigger than XL type.

Technical paramters:

Star Coupling

Model: XLDType

Norminal Torque: 34N. M – 35000N. M

Connection: Shaft hole

Shaft Hole Diameter(d1,d2): 6mm – 220mm

Shaft Hole Length (L): 25mm – 195mm

The elastomer hardness is 92shA

Small dimensions, low weight and low mass moments of inertia yet transmit high torques

Running quality and long service life of the coupling are improved by accurate all-over machining

Their application is ideal for transmitting torque while damping torsional vibrations and absorbing shocks produced by the uneven operation of certain prime movers

Axial plug-in,Maintenance-free, easy assembly, easy to inspect visually

Working temperature -35~80ºC

Failsafe

Same function as CHINAMFG which is made in Germany

The bushing is made of aluminum allory or steel, which is especially suitable for heavy-duty transmission,especially suitable for lifts, rolling mills, construction machinery and Metallurgy, mining, transportation, petroleum, chemical, ships, textile, light industry, agricultural machinery, printing machines and pumps, fans, compressors, machine tools and other mechanical equipment and industry shaft transmission.

Other customized design.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Contribution of Elastic Couplings to Rotating System Efficiency

Elastic couplings play a significant role in enhancing the overall efficiency of rotating systems by providing various benefits:

1. Vibration Damping: Elastic couplings absorb and dampen vibrations and shocks that arise from the operation of rotating machinery. By minimizing these vibrations, elastic couplings reduce wear and tear on components, leading to smoother operation and extended component lifespan.

2. Misalignment Compensation: Rotating systems often experience misalignments due to factors like thermal expansion, installation errors, or operational conditions. Elastic couplings can accommodate angular, axial, and radial misalignments, ensuring consistent power transmission and reducing stress on connected components.

3. Shock Absorption: In applications with sudden starts, stops, or load changes, elastic couplings absorb and distribute shock loads. This prevents sudden jolts that could damage the machinery or cause mechanical failures.

4. Torsional Vibration Reduction: Elastic couplings help minimize torsional vibrations, which can lead to resonance and cause structural damage. By damping these vibrations, elastic couplings prevent energy loss and ensure smooth operation.

5. Energy Efficiency: The ability of elastic couplings to reduce vibrations, misalignments, and shock loads leads to improved energy efficiency. The machinery experiences fewer energy losses due to internal friction and component stress.

Elastic couplings enhance the reliability, longevity, and performance of rotating systems, ultimately leading to reduced downtime, maintenance costs, and overall operational inefficiencies.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-04-30

China Standard Power Transmission Abrasion-Resistant Elastic Curved Flexible CHINAMFG Star Drive Spider Plum PU Gasket Jaw Rubber Type Coupling

Product Description

Power Transmission Abrasion-Resistant Elastic Curved Flexible CHINAMFG Star Drive Spider Plum PU Gasket Jaw Rubber Type Coupling

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Features

1. Hubs made of cast iron GG25.

2. Torsionally flexible, maintenance free, vibration-damping.

3. Axial plug-in, fail-safe.

4. Varying elastomer hardness of spiders.

5. Compact design with small flywheel effect.

6 Easy assembly / dis-assembly of the coupling hubs Short mounting length.

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Limitations and Disadvantages of Elastic Couplings

While elastic couplings offer various benefits, they also come with certain limitations and disadvantages that engineers and designers need to consider:

- Torsional Stiffness: Elastic couplings provide flexibility, but this can lead to lower torsional stiffness compared to rigid couplings. In applications requiring high torsional stiffness, elastic couplings might not be the ideal choice.

- Energy Loss: Due to the elastic nature of the material, a portion of the transmitted torque can be absorbed as deformation energy in the elastomer. This can result in energy losses and reduce overall efficiency.

- Wear and Fatigue: The elastomer element in elastic couplings can experience wear, fatigue, and deterioration over time, especially in applications with high loads or extreme operating conditions. Regular maintenance and monitoring are essential to ensure proper functionality.

- Temperature Sensitivity: Some elastomer materials used in elastic couplings might be sensitive to temperature fluctuations. Extreme temperatures can affect the properties of the elastomer and compromise the coupling’s performance.

- Alignment Requirements: While elastic couplings can accommodate minor misalignments, excessive misalignment can still lead to premature wear and reduced coupling lifespan. Proper alignment remains important for optimal performance.

Engineers and designers must carefully assess the specific requirements of their applications to determine if the advantages of elastic couplings outweigh the potential limitations and disadvantages.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Elastic Coupling: Function and Working in Mechanical Systems

An elastic coupling is a type of coupling used in mechanical systems to connect two shafts and transmit torque while allowing for a certain degree of misalignment and flexibility. It consists of two hubs, each connected to a shaft, and an elastic element placed between the hubs.

The elastic element, often made of rubber or elastomer material, serves as a flexible medium that can absorb shocks, vibrations, and angular misalignments between the connected shafts. When torque is applied to one shaft, the elastic element deforms and compresses, allowing the coupling to transmit torque from one shaft to the other while compensating for minor misalignments.

As the elastic element absorbs vibrations and shocks, it helps reduce wear and tear on the connected machinery and enhances overall system efficiency. Elastic couplings are commonly used in applications where precise alignment between shafts is challenging or where vibration damping is crucial.

Overall, the elastic coupling’s design enables it to provide a balance between torque transmission and flexibility, making it a valuable component in various mechanical systems.

editor by CX 2024-04-23

China best Hydraulic Machinery Steel High Rotations Speed Flexible Element Length Extending Motor Disc Coupling for Power Transmission coupling bushing

Product Description

hydraulic machinery steel High rotations speed flexible element length extending motor disc coupling for power transmission

DISC Couplings

Advantage:

1. Widely used in various mechanical and hydraulic fields

2. Low-cost maintenance

3. Compensation for axial, radial and angular misalignment

4. Convenient axial plugging assembly

5. Installed horizontally and vertically without using any social tools.

6. Excellent mechanical properties

7. No brittlement at low temperature

8. Good slippery and frictional properties

9. Exellent electrical insulation

Application:

1. Printing machinery / Packing machinery / Wood-working machinery etc large-scale mechanical equipment

2. Repair replacement

Company Information:

| Standard Or Nonstandard: | Nonstandard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | <10N.M |

| Bore Diameter: | 19mm |

| Speed: | 8000r/M |

| Structure: | Rigid |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by CX 2023-06-09

China Power Transmission Flexible Rigid Coupling for Stepper Motor with Best Sales

Product Description

Solution Description:

Coupling is used to link the 2 diverse corporations shaft (driving shaft and driven shaft) to rotate to typical transmission torque of mechanical areas.The overloaded power transmission at substantial speed, some coupling and buffer, vibration and boost the role of shaft system dynamic functionality.Coupling consists of 2 elements, respectively, and the driving shaft and driven shaft link.

| Brand name | SHAC |

| Uncooked materials | Aluminum |

| Inner Diameter | four-60MM |

| Size | twenty five-140MM |

| Design amount | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+interior box.In accordance to customer’s ask for |

| Sample | Cost-free sample and catalogue accessible |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC machines, health-related and foodstuff equipment, health and fitness equipment, packaging machinery, printing machinery, and other machinery supporting gear. |

Services:

one,Our Crew:

We have skilled and competent crew of marketing and income reps to serve our valued customers with the best items and unsurpassed services.And have specialist engineers team to assessment and development the new precision products,and make the OEM tailored a lot more easily,knowledgeable QC team to examination the merchandise quaity guarantee the merchandise top quality just before supply out.

two,Our merchandise:

High quality is the daily life .We use only the very best high quality content to make certain the precision of our

Item.All products we offered out are strictly picked and tested by our QC section.

three,Payment:

We take payment via TT (Lender transfer), L/C,Western Union.

four,Shipping and delivery method:

Including DHL, UPS, TNT, FEDEX,EMS, Airfreight and by Sea,as buyer needed.

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | Different Size as Requirement |

| Torque: | More Than 10n.M |

| Bore Diameter: | 4mm~60mm,Different Size with Different |

| Speed: | Different Size Maximum Rpm Different as Standard |

| Structure: | Flexible |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand | SHAC |

| Raw material | Aluminum |

| Inner Diameter | 4-60MM |

| Length | 25-140MM |

| Model number | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+inner box.According to customer‘s request |

| Sample | Free sample and catalogue available |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC machines, medical and food machinery, fitness machinery, packaging machinery, printing machinery, and other machinery supporting equipment. |

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | Different Size as Requirement |

| Torque: | More Than 10n.M |

| Bore Diameter: | 4mm~60mm,Different Size with Different |

| Speed: | Different Size Maximum Rpm Different as Standard |

| Structure: | Flexible |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand | SHAC |

| Raw material | Aluminum |

| Inner Diameter | 4-60MM |

| Length | 25-140MM |

| Model number | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+inner box.According to customer‘s request |

| Sample | Free sample and catalogue available |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC machines, medical and food machinery, fitness machinery, packaging machinery, printing machinery, and other machinery supporting equipment. |

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by czh 2023-01-04