Product Description

Mining Use Elastic Spider Shaft Coupling Connection Jaw Type Electric Motor Belt Conveyor Flexible Spider Coupling for Cement

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Features

1. Hubs made of cast iron GG25.

2. Torsionally flexible, maintenance free, vibration-damping.

3. Axial plug-in, fail-safe.

4. Varying elastomer hardness of spiders.

5. Compact design with small flywheel effect.

6 Easy assembly / dis-assembly of the coupling hubs Short mounting length.

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Limitations and Disadvantages of Elastic Couplings

While elastic couplings offer various benefits, they also come with certain limitations and disadvantages that engineers and designers need to consider:

- Torsional Stiffness: Elastic couplings provide flexibility, but this can lead to lower torsional stiffness compared to rigid couplings. In applications requiring high torsional stiffness, elastic couplings might not be the ideal choice.

- Energy Loss: Due to the elastic nature of the material, a portion of the transmitted torque can be absorbed as deformation energy in the elastomer. This can result in energy losses and reduce overall efficiency.

- Wear and Fatigue: The elastomer element in elastic couplings can experience wear, fatigue, and deterioration over time, especially in applications with high loads or extreme operating conditions. Regular maintenance and monitoring are essential to ensure proper functionality.

- Temperature Sensitivity: Some elastomer materials used in elastic couplings might be sensitive to temperature fluctuations. Extreme temperatures can affect the properties of the elastomer and compromise the coupling’s performance.

- Alignment Requirements: While elastic couplings can accommodate minor misalignments, excessive misalignment can still lead to premature wear and reduced coupling lifespan. Proper alignment remains important for optimal performance.

Engineers and designers must carefully assess the specific requirements of their applications to determine if the advantages of elastic couplings outweigh the potential limitations and disadvantages.

Advancements in Elastic Coupling Technology

Recent advancements in elastic coupling technology have led to improved performance and capabilities. Some notable developments include:

- Enhanced Materials: The use of advanced materials, such as high-performance elastomers and composites, has resulted in elastic couplings that offer higher strength, durability, and resistance to wear and fatigue.

- Optimized Designs: Engineers are employing advanced computer simulations and modeling techniques to optimize the design of elastic couplings. This has led to designs that provide better torsional flexibility, reduced backlash, and improved performance in demanding conditions.

- Vibration Dampening: Advancements in elastic coupling technology have focused on improving vibration dampening properties. This is particularly important in applications where minimizing vibration and shock is crucial for the machinery’s precision and longevity.

- Customization: Modern elastic coupling manufacturers offer more options for customization, allowing engineers to select the best coupling configuration, size, and material for their specific application requirements.

- Smart Couplings: Some elastic couplings now incorporate sensors and monitoring technology to provide real-time data on coupling performance, misalignment, and wear. This data can aid in predictive maintenance and enhance overall system reliability.

These advancements in elastic coupling technology continue to contribute to the efficiency, reliability, and overall performance of machinery systems in various industries.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-04-08

China wholesaler Mh 55~ Mh230 Cast Iron Elastic Shaft Coupling Flexible Jaw Couplings with Rubber PU Spider Electric Motor Couplings

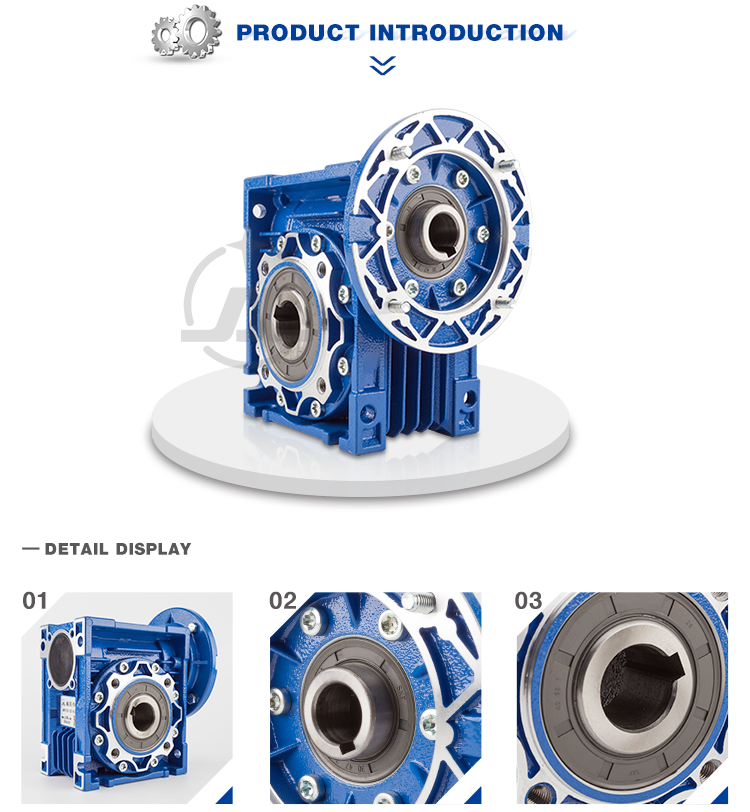

Product Description

MH coupling

Product Description

MH coupling

1. Made of high grade cast iron.

2. NBR rubber material: excellent oil resistance, similar to TM, ACM and fluororubber.

Good wear resistance, heat resistance, aging resistance and air tightness.

Basic acid-base resistance.

3. Working temperature: – 40 ~ + 120 ºC

Related Products

Company Information

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Material Selection and Design Durability of Elastic Couplings

The choice of materials for elastic couplings significantly influences their design and overall durability. Material selection affects factors such as flexibility, torsional stiffness, fatigue resistance, and resistance to environmental conditions. Here’s how material selection plays a crucial role:

- Elastomer Material: The elastomer used in elastic couplings determines the coupling’s flexibility, vibration absorption capabilities, and resilience. Common elastomers include natural rubber, synthetic rubber, and polyurethane. The selected elastomer should provide the desired level of elasticity and durability while maintaining its properties over time.

- Hub and Spacer Material: The hubs and spacers of elastic couplings are typically made from metals like steel, aluminum, or alloy materials. These components need to be strong enough to transmit torque while accommodating misalignments and vibrations. The material should also resist wear, corrosion, and fatigue.

- Bolt or Pin Material: Bolts or pins used to connect the hubs and elastomer element must possess sufficient strength to handle the torsional forces and loads. They should be made from materials with high tensile strength and corrosion resistance.

- Environmental Factors: Depending on the application environment, material selection should consider factors such as temperature, moisture, chemicals, and UV exposure. The chosen materials should be able to withstand these conditions without deterioration.

Ultimately, a well-considered material selection enhances the coupling’s durability, operational performance, and resistance to wear, ensuring that the elastic coupling can reliably function under varying conditions and loads.

Advancements in Elastic Coupling Technology

Recent advancements in elastic coupling technology have led to improved performance and capabilities. Some notable developments include:

- Enhanced Materials: The use of advanced materials, such as high-performance elastomers and composites, has resulted in elastic couplings that offer higher strength, durability, and resistance to wear and fatigue.

- Optimized Designs: Engineers are employing advanced computer simulations and modeling techniques to optimize the design of elastic couplings. This has led to designs that provide better torsional flexibility, reduced backlash, and improved performance in demanding conditions.

- Vibration Dampening: Advancements in elastic coupling technology have focused on improving vibration dampening properties. This is particularly important in applications where minimizing vibration and shock is crucial for the machinery’s precision and longevity.

- Customization: Modern elastic coupling manufacturers offer more options for customization, allowing engineers to select the best coupling configuration, size, and material for their specific application requirements.

- Smart Couplings: Some elastic couplings now incorporate sensors and monitoring technology to provide real-time data on coupling performance, misalignment, and wear. This data can aid in predictive maintenance and enhance overall system reliability.

These advancements in elastic coupling technology continue to contribute to the efficiency, reliability, and overall performance of machinery systems in various industries.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-04-08

China wholesaler Cast Iron Mh Shaft Couplings for Electric Motor Flexible Jaw Spider Elastic Coupling Quick Release Rubber Coupling

Product Description

Cast Iron Mh Shaft Couplings for Electric Motor Flexible Jaw Spider Elastic Coupling Quick Release Rubber Coupling

Product Description

MH coupling

1. Made of high grade cast iron.

2. NBR rubber material: excellent oil resistance, similar to TM, ACM and fluororubber.

Good wear resistance, heat resistance, aging resistance and air tightness.

Basic acid-base resistance.

3. Working temperature: – 40 ~ + 120 ºC

Related products:

Production workshop:

Company information:

Material Selection and Design Durability of Elastic Couplings

The choice of materials for elastic couplings significantly influences their design and overall durability. Material selection affects factors such as flexibility, torsional stiffness, fatigue resistance, and resistance to environmental conditions. Here’s how material selection plays a crucial role:

- Elastomer Material: The elastomer used in elastic couplings determines the coupling’s flexibility, vibration absorption capabilities, and resilience. Common elastomers include natural rubber, synthetic rubber, and polyurethane. The selected elastomer should provide the desired level of elasticity and durability while maintaining its properties over time.

- Hub and Spacer Material: The hubs and spacers of elastic couplings are typically made from metals like steel, aluminum, or alloy materials. These components need to be strong enough to transmit torque while accommodating misalignments and vibrations. The material should also resist wear, corrosion, and fatigue.

- Bolt or Pin Material: Bolts or pins used to connect the hubs and elastomer element must possess sufficient strength to handle the torsional forces and loads. They should be made from materials with high tensile strength and corrosion resistance.

- Environmental Factors: Depending on the application environment, material selection should consider factors such as temperature, moisture, chemicals, and UV exposure. The chosen materials should be able to withstand these conditions without deterioration.

Ultimately, a well-considered material selection enhances the coupling’s durability, operational performance, and resistance to wear, ensuring that the elastic coupling can reliably function under varying conditions and loads.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Factors to Consider When Selecting an Elastic Coupling

Engineers must carefully evaluate several factors when selecting an appropriate elastic coupling for a specific application. These factors ensure that the coupling can effectively meet the requirements of the machinery and system:

- Torque Transmission: Consider the amount of torque that needs to be transmitted between the connected shafts. Ensure that the coupling’s torque rating matches or exceeds the application’s torque requirements.

- Misalignment Compensation: Evaluate the expected misalignments between the shafts, such as angular, parallel, and axial misalignments. Choose a coupling with the appropriate flexibility and misalignment capacity to accommodate these variations.

- Vibration Dampening: Determine the level of vibration present in the system and select a coupling with the necessary torsional elasticity to dampen vibrations and provide smoother operation.

- Operating Speed: Consider the rotational speed of the connected shafts. Some elastic couplings may have speed limitations, so choose a coupling that can handle the desired operating speed without issues.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, and the presence of contaminants. Choose a coupling material that can withstand the conditions and resist corrosion or degradation.

- Space Limitations: Take into account the available space for installing the coupling. Some couplings may have compact designs that are better suited for confined spaces.

- Shaft Sizes: Ensure that the coupling is compatible with the diameters of the connected shafts. Verify the coupling’s bore sizes and choose one that matches the shaft sizes.

- Installation and Maintenance: Consider the ease of installation and maintenance. Some couplings have simpler installation procedures, while others might require more complex procedures.

- Cost: Evaluate the budget for the coupling. While high-performance couplings might have added benefits, they could also come at a higher cost. Balance the performance requirements with budget constraints.

By carefully assessing these factors and selecting the appropriate elastic coupling, engineers can ensure optimal performance, longevity, and reliability of the machinery and systems they design.

editor by CX 2023-10-09

China China CNC Electric Motor Steel Coupling Gear Shaft Coupling Shafts coupling constant

Composition: Worm

Content: Stainless metal, Aluminum, copper, brass, stainless metal, Carbon steel or OEM

Coatings: Aluminum, brass, stainless steel, steel, iron, alloy, zinc etc.

Torque Capacity: Custom made-Producing

Duration: Request

Design Amount: gear shaft coupling

Name: gear shaft coupling

Tolerance: ±0.01mm-.

Internet:

Skype: CZPT 0571

Insert:No.39 Jingfu West Road ,Yangkengtang Village,DalangTown,HangZhou,ZheJiang , CZPT S sequence equivalent SC right – angle planetary equipment device China

Types of Couplings

A coupling is a device that connects two shafts and transmits power from one to the other. Its main purpose is to join two pieces of rotating equipment. It also allows for some degree of misalignment or end movement. Here are a few examples of coupling types: Beam coupling, Flexible coupling, Magnetic coupling, and Shaft coupling.

Beam coupling

Beam couplings are used to couple motors and other devices. They are available in several types, including flexible, slit, and rigid beam couplings. Each has unique properties and characteristics. These couplings are best for applications requiring a high level of precision and long life. They are also a practical solution for the connection of stepping and servo motors with screw rods.

Beam couplings are usually made of stainless steel or aluminum alloy, and feature spiral and parallel cut designs. Multiple cuts allow the coupling to accommodate multiple beams and improve angular and parallel misalignment tolerances. Additionally, beam couplings are comparatively cheaper than other types of rotary joints, and they require minimal maintenance.

The materials of a beam coupling should be considered early in the specification process. They are typically made of aluminum or stainless steel, but they can also be manufactured from Delrin, titanium, and other engineering grade materials. Beam couplings are often available in multiple sizes to fit specific shaft diameters.

Beam couplings are a key component of motion control systems. They provide excellent characteristics when used properly, and they are a popular choice for many applications. A thorough understanding of each type of coupling will help to prevent coupling failure and enhance system performance. Therefore, it is important to choose the right coupling for your application.

Various types of beam couplings have unique advantages and disadvantages. The FCR/FSR design has two sets of three beams. It is available in both metric and inch shaft sizes. The FCR/FSR couplings are ideal for light-duty power transmission applications. A metric shaft is more suitable for these applications, while an inch shaft is preferred for heavier duty applications.

Two types of beam couplings are available from Ruland. The Ruland Flexible beam coupling has a multi-helical cut design that offers a greater flexibility than commodity beam couplings. This design allows for higher torque capabilities while minimizing wind-up. In addition, it is also more durable than its commodity counterparts.

Flexible coupling

A flexible coupling is a versatile mechanical connection that allows for the easy coupling of two moving parts. The design of these couplings allows for a variety of stiffness levels and can address a variety of problems, such as torsional vibrations or critical speed. However, there are a number of tradeoffs associated with flexible couplings.

One of the biggest issues is the installation of the coupling, which requires stretching. This problem can be exacerbated by cold temperatures. In such a case, it is vital to install the coupling properly. Using a gear clamp is one of the most important steps in a successful installation. A gear clamp will keep the coupling in place and prevent it from leaking.

Another common type of flexible coupling is the gear coupling. These couplings are composed of two hubs with crowned external gear teeth that mesh with two internally splined flanged sleeves. The massive size of the teeth makes them resemble gears. Gear couplings offer good torque characteristics but require periodic lubrication. These couplings can also be expensive and have a limited number of applications.

Another type of flexible coupling is the SDP/SI helical coupling. These couplings can accommodate axial motion, angular misalignment, and parallel offset. This design incorporates a spiral pattern that makes them flexible. These couplings are available in stainless steel and aluminum.

A flexible coupling has a wide range of applications. Generally, it is used to connect two rotating pieces of equipment. Depending on its design, it can be used to join two pieces of machinery that move in different directions. This type of coupling is a type of elastomeric coupling, which has elastic properties.

There are many types of flexible couplings available for different types of applications. The purpose of a flexible coupling is to transmit rotational power from one shaft to another. It is also useful for transmitting torque. However, it is important to note that not all flexible couplings are created equally. Make sure to use a reputable brand for your coupling needs. It will ensure a reliable connection.

The simplest and most commonly used type of flexible coupling is the grid coupling. This type of coupling uses two hubs with slotted surfaces. The steel grid is allowed to slide along these slots, which gives it the ability to flex. The only limitation of this type of coupling is that it can only tolerate a 1/3 degree misalignment. It can transmit torques up to 3,656 Nm.

Magnetic coupling

Magnetic coupling is a technique used to transfer torque from one shaft to another using a magnetic field. It is the most common type of coupling used in machinery. It is highly effective when transferring torque from a rotating motor to a rotating shaft. Magnetic couplings can handle high torques and high speeds.

Magnetic coupling is described by the energy difference between a high-spin state and a broken symmetry state, with the former being the energy of a true singlet state. In single-determinant theories, this energy difference is called the Kij. Usually, the broken-symmetry state is a state with two interacting local high-spin centers.

The magnetic coupling device is regarded as a qualitative leap in the reaction still industry. It has solved a number of problems that had plagued the industry, including flammability, explosiveness, and leakage. Magnetic couplings are a great solution for many applications. The chemical and pharmaceutical industries use them for various processes, including reaction stills.

Magnetic couplings are a good choice for harsh environments and for tight spaces. Their enclosed design keeps them fluid and dust-proof. They are also corrosion-resistant. In addition, magnetic couplings are more affordable than mechanical couplings, especially in areas where access is restricted. They are also popular for testing and temporary installations.

Another use for magnetic coupling is in touch screens. While touch screens use capacitive and resistive elements, magnetic coupling has found a cool new application in wireless charging. While the finger tracking on touch screens may seem like a boley job, the process is very sensitive. The devices that use wireless charging need to have very large coils that are locked into resonant magnetic coupling.

Magnetic couplings also help reduce hydraulic horsepower. They cushion starts and reduce alignment problems. They can also improve flow in oversized pumps. A magnetic coupling with an 8 percent air gap can reduce hydraulic HP by approximately 27 percent. In addition, they can be used in aggressive environments. They also help reduce repair costs.

Magnetic couplings are a great choice for pumps and propeller systems because they have the added advantage of being watertight and preventing shaft failure. These systems also have the benefit of not requiring rotating seals.

Shaft coupling

A shaft coupling joins two shafts and transmits rotational motion. Generally, shaft couplings allow for some degree of misalignment, but there are also torque limiters. Selecting the right coupling can save you time and money and prevent equipment downtime. Here are the main features to consider when purchasing a coupling for your application.

Shaft couplings should be easy to install and disassemble, transmit full power to the mated shaft, and reduce shock loads. A shaft coupling that does not have projecting parts should be used for machines that move or rotate at high speeds. Some types of shaft couplings are flexible while others are rigid.

Shaft couplings can be used in a variety of applications, including piping systems. They can be used to connect shafts that are misaligned and help maintain alignment. They can also be used for vibration dampening. Shaft couplings also allow shafts to be disconnected when necessary.

Shaft couplings can accommodate a certain amount of backlash, but this backlash must be well within the tolerance set by the system. Extremely high backlash can break the coupling and cause excessive wear and stress. In addition, excessive backlash can lead to erratic alignment readings. To avoid these issues, operators must reduce backlash to less than 2deg.

Shaft couplings are often referred to by different names. Some are referred to as “sliced” couplings while others are known as “slit” couplings. Both types offer high torque and torsional stiffness. These couplings are typically made from metals with various alloys, such as acetal, stainless steel, or titanium.

CZPT Pulley produces shaft couplings for a variety of applications. These products are used in high-power transmission systems. They have several advantages over friction couplings. In addition to minimizing wear, they don’t require lubrication. They are also capable of transmitting high torque and high speeds.

Another type of shaft coupling is the universal coupling. It is used to transmit power to multiple machines with different spindles. Its keyed receiving side and flanges allow it to transmit power from one machine to another.

editor by czh 2023-02-22

China manufacturer Easy to install Torsionally flexible Rubber Electric Motor jaw flexible Shaft Couplings fenner coupling

Guarantee: 1 several years

Relevant Industries: Building Content Retailers, Producing Plant, Machinery Repair Outlets, Retail, Building performs

Tailored assistance: OEM, ODM

Construction: Equipment

Versatile or Rigid: Flexible

Standard or Nonstandard: Regular

Material: Aluminum alloy

Merchandise name: jaw versatile Shaft Couplings

Application: Shaft coupling

Entire body Substance: Aluminum alloy

Colour: Grey

MOQ: 1 Set

Dimension: D30~125

Weight: 80g~5100g

Framework Sort: Claw Cross

Length: 30mm~140mm

Good quality: High precision

Packaging Particulars: Carton/wooden box

Port: HangZhou HangZhou

| TYPE | d1 d2 | ||||||||||||

| internal diameter | D | L | L1 | A | B | E | C | ||||||

| AGS20 | 4 5 6 8 10 | 20 | 30 | 10 | 5 | 7.five | |||||||

| AGS25 | 5 6 8 10 twelve | 25 | 34 | 11 | 5 | 9 | |||||||

| AGS30 | 5 6 8 | 30 | 35/forty | 11 | 5 | 11.five | 10 | 1.five | |||||

| AGS40 | 19 20 | 40 | 50/66 | 25 | 10 | 15.5 | 12 | 2 | |||||

| AGS55 | 22 24 | 55 | 78 | 30 | 10.five | 20 | 14 | 2 | |||||

| AGS65 | 65 | 90 | 35 | 13 | 25 | 15 | 2.5 | ||||||

| AGS80 | 80 | 114 | 45 | 15 | 30 | 18 | 3 | ||||||

| AGS95 | 42 | 95 | 126 | 50 | 18 | 32 | 20 | 3 | |||||

| AGS105 | 105 | 140 | 56 | 20 | 36 | 21 | 3 | ||||||

Types of Splines

There are four types of splines: Involute, Parallel key, helical, and ball. Learn about their characteristics. And, if you’re not sure what they are, you can always request a quotation. These splines are commonly used for building special machinery, repair jobs, and other applications. The CZPT Manufacturing Company manufactures these shafts. It is a specialty manufacturer and we welcome your business.

Involute splines

The involute spline provides a more rigid and durable structure, and is available in a variety of diameters and spline counts. Generally, steel, carbon steel, or titanium are used as raw materials. Other materials, such as carbon fiber, may be suitable. However, titanium can be difficult to produce, so some manufacturers make splines using other constituents.

When splines are used in shafts, they prevent parts from separating during operation. These features make them an ideal choice for securing mechanical assemblies. Splines with inward-curving grooves do not have sharp corners and are therefore less likely to break or separate while they are in operation. These properties help them to withstand high-speed operations, such as braking, accelerating, and reversing.

A male spline is fitted with an externally-oriented face, and a female spline is inserted through the center. The teeth of the male spline typically have chamfered tips to provide clearance with the transition area. The radii and width of the teeth of a male spline are typically larger than those of a female spline. These specifications are specified in ANSI or DIN design manuals.

The effective tooth thickness of a spline depends on the involute profile error and the lead error. Also, the spacing of the spline teeth and keyways can affect the effective tooth thickness. Involute splines in a splined shaft are designed so that at least 25 percent of the spline teeth engage during coupling, which results in a uniform distribution of load and wear on the spline.

Parallel key splines

A parallel splined shaft has a helix of equal-sized grooves around its circumference. These grooves are generally parallel or involute. Splines minimize stress concentrations in stationary joints and allow linear and rotary motion. Splines may be cut or cold-rolled. Cold-rolled splines have more strength than cut spines and are often used in applications that require high strength, accuracy, and a smooth surface.

A parallel key splined shaft features grooves and keys that are parallel to the axis of the shaft. This design is best suited for applications where load bearing is a primary concern and a smooth motion is needed. A parallel key splined shaft can be made from alloy steels, which are iron-based alloys that may also contain chromium, nickel, molybdenum, copper, or other alloying materials.

A splined shaft can be used to transmit torque and provide anti-rotation when operating as a linear guide. These shafts have square profiles that match up with grooves in a mating piece and transmit torque and rotation. They can also be easily changed in length, and are commonly used in aerospace. Its reliability and fatigue life make it an excellent choice for many applications.

The main difference between a parallel key splined shaft and a keyed shaft is that the former offers more flexibility. They lack slots, which reduce torque-transmitting capacity. Splines offer equal load distribution along the gear teeth, which translates into a longer fatigue life for the shaft. In agricultural applications, shaft life is essential. Agricultural equipment, for example, requires the ability to function at high speeds for extended periods of time.

Involute helical splines

Involute splines are a common design for splined shafts. They are the most commonly used type of splined shaft and feature equal spacing among their teeth. The teeth of this design are also shorter than those of the parallel spline shaft, reducing stress concentration. These splines can be used to transmit power to floating or permanently fixed gears, and reduce stress concentrations in the stationary joint. Involute splines are the most common type of splined shaft, and are widely used for a variety of applications in automotive, machine tools, and more.

Involute helical spline shafts are ideal for applications involving axial motion and rotation. They allow for face coupling engagement and disengagement. This design also allows for a larger diameter than a parallel spline shaft. The result is a highly efficient gearbox. Besides being durable, splines can also be used for other applications involving torque and energy transfer.

A new statistical model can be used to determine the number of teeth that engage for a given load. These splines are characterized by a tight fit at the major diameters, thereby transferring concentricity from the shaft to the female spline. A male spline has chamfered tips for clearance with the transition area. ANSI and DIN design manuals specify the different classes of fit.

The design of involute helical splines is similar to that of gears, and their ridges or teeth are matched with the corresponding grooves in a mating piece. It enables torque and rotation to be transferred to a mate piece while maintaining alignment of the two components. Different types of splines are used in different applications. Different splines can have different levels of tooth height.

Involute ball splines

When splines are used, they allow the shaft and hub to engage evenly over the shaft’s entire circumference. Because the teeth are evenly spaced, the load that they can transfer is uniform and their position is always the same regardless of shaft length. Whether the shaft is used to transmit torque or to transmit power, splines are a great choice. They provide maximum strength and allow for linear or rotary motion.

There are three basic types of splines: helical, crown, and ball. Crown splines feature equally spaced grooves. Crown splines feature involute sides and parallel sides. Helical splines use involute teeth and are often used in small diameter shafts. Ball splines contain a ball bearing inside the splined shaft to facilitate rotary motion and minimize stress concentration in stationary joints.

The two types of splines are classified under the ANSI classes of fit. Fillet root splines have teeth that mesh along the longitudinal axis of rotation. Flat root splines have similar teeth, but are intended to optimize strength for short-term use. Both types of splines are important for ensuring the shaft aligns properly and is not misaligned.

The friction coefficient of the hub is a complex process. When the hub is off-center, the center moves in predictable but irregular motion. Moreover, when the shaft is centered, the center may oscillate between being centered and being off-center. To compensate for this, the torque must be adequate to keep the shaft in its axis during all rotation angles. While straight-sided splines provide similar centering, they have lower misalignment load factors.

Keyed shafts

Essentially, splined shafts have teeth or ridges that fit together to transfer torque. Because splines are not as tall as involute gears, they offer uniform torque transfer. Additionally, they provide the opportunity for torque and rotational changes and improve wear resistance. In addition to their durability, splined shafts are popular in the aerospace industry and provide increased reliability and fatigue life.

Keyed shafts are available in different materials, lengths, and diameters. When used in high-power drive applications, they offer higher torque and rotational speeds. The higher torque they produce helps them deliver power to the gearbox. However, they are not as durable as splined shafts, which is why the latter is usually preferred in these applications. And while they’re more expensive, they’re equally effective when it comes to torque delivery.

Parallel keyed shafts have separate profiles and ridges and are used in applications requiring accuracy and precision. Keyed shafts with rolled splines are 35% stronger than cut splines and are used where precision is essential. These splines also have a smooth finish, which can make them a good choice for precision applications. They also work well with gears and other mechanical systems that require accurate torque transfer.

Carbon steel is another material used for splined shafts. Carbon steel is known for its malleability, and its shallow carbon content helps create reliable motion. However, if you’re looking for something more durable, consider ferrous steel. This type contains metals such as nickel, chromium, and molybdenum. And it’s important to remember that carbon steel is not the only material to consider.

editor by czh

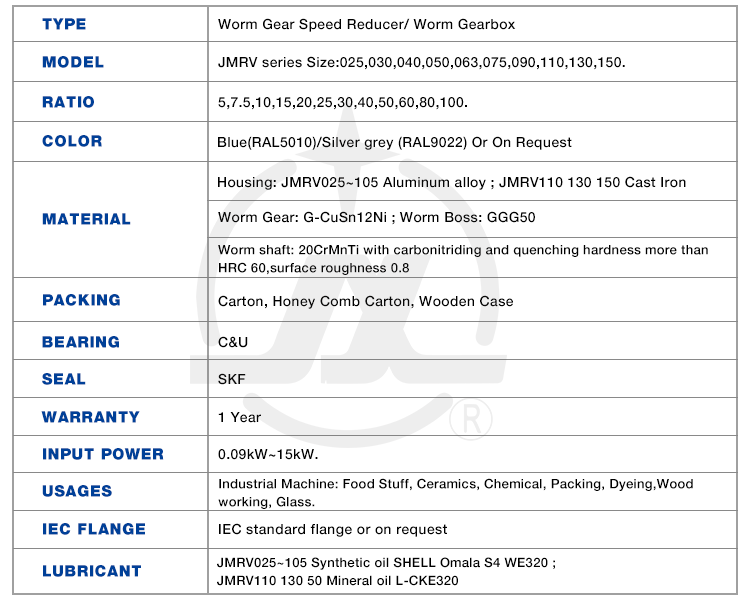

Best China manufacturer & factory High in Ryazan Russian Federation quality aluminium variable speed reducer electric high rpm reduction worm motor gearbox With high quality best price

Our principal products are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical basic bearings, Observe roller Bearings for Guideway, Roller Bearings, Mix Bearings for forklifts, Drinking water Pump Bearings, SNR Auto Bearings and all types of Spherical Bearings.

Overview

Swift Information

- Applicable Industries:

-

Design functions

- Manufacturer Name:

-

OEM

- Gearing Arrangement:

-

Worm

- Adhering tWorm Gear reducers are utilized in electrical power transmission applications demanding high ratio speed reduction in a constrained area. The gears are employed on right angle, non-intersecting shafts. When effectively aligned, worms and worm gears are the quietest and smoothest form of gearing. One particular downside of worm gearing is as the ratio of this gearing enhance, the performance of the gearing decreases. A worm equipment reducer is a right angle speed reducer that enables the highest pace reduction in the smallest package deal.o “Survival by Top quality, Improvement by Technological innovation & Credit”, The organization will consistently enhance item functionality to meet up with the increasing consumer specifications in the arduous style of function. Output Torque:

-

fifteen~1700Nm

- Enter Velocity:

-

500~2800/min

- Output Pace:

-

five~560/min

- Item title:

-

velocity reducer electric powered higher rpm reduction worm motor gearbox

- Application:

-

Foods Things, Ceramics, Chemical, Packing, Dyeing,Wood doing work, Glass.

PTO Adapters To stay away from likely connectivity concerns, you may want to think about a PTO Adapter for your tractor. The PTO adapter extends the relationship to the employ, supplying additional area for the PTO shaft to turn with out touching the Arm Weldment or other components of your tractor or the put into action.

- Coloration:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

- Ratio:

-

five,7.5,10,fifteen,twenty,25,30,forty,50,60,80,one hundred.

- Warranty:

-

one Year

Source Capability

- Offer Capacity:

- 36000 Piece/Items per Month

Packaging & Delivery

- Packaging Particulars

- Transparent box packaging, or coloration box packaging, it also can be tailored.

- Port

- Ningbo/Shanghai

On the internet Customization

Large quality aluminium variable speed reducer electric substantial rpm reduction worm motor gearbox

Q1.How to pick a gearbox which meets our prerequisite?

A1: You can refer to our catalogue to choose the gearbox or we can help to pick when you offer

the complex data of output torque, output pace and motor parameter and so forth.

Q2.How is your value? Can you offer you any price cut?

A2: We will give the very best cost we can foundation on your needs and the quantities.

Q3.Do you offer any browsing?

A3: Sure! We sincerely invite you to go to us! We can decide you from airport, railway station and so on.

Also, we can organize housing for you. Please permit us know in innovative.

This autumn.When is the best time to speak to you?

A4: You can speak to us by e-mail any time, we will reply you as before long as attainable.

Q5.How lengthy will it just take for the lead time?

A5: For our standard design, please refer to the various merchandise internet pages to verify the direct time.

For the OEM/ODM goods, remember to contact us for further data.

Best China manufacturer & factory china in Uyo Nigeria supplier NMRV RV 90 Degree aluminium Transmission Worm Gear Gearbox with electric motor With high quality best price

our items are selling effectively in the American, European, South American and Asian marketplaces. a specialized supplier of a complete range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Specifics

- Applicable Industries:

-

Producing Plant

- Pole:

-

one particular two 3 four six Stage

- Ratio:

-

thirty

- Housing Content:

-

Forged Iron

- Doing work temperature:

-

-forty~45℃

- Application:

-

generation products cleaning soap

- Approach:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting PositiTECHNOLOGY Chief IN THE DRIVES SECTOR Controlling movement with the highest precision – this challenge has been driving WITTENSTEIN for above 30 many years now. This fantastic willpower has served us become an undisputed international technology and good quality chief.on:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Grey,Pink

- Kind:

-

ninety Degree aluminium Transmission Worm Gear Gearbox with electric powered motor

Packaging & Shipping and delivery

-

Direct Time

: -

Amount(Luggage) one – 1 >1 Est. Time(times) three To be negotiated

On-line Customization

Merchandise Description

YOUR Expert MANUFACTURE

—— Given that 1995

NMRV Worm Equipment Reducer Gearbox

EPG——industrial makers

NMRV RV 90 Degree aluminium Transmission Worm Gear Gearbox with electric powered motor

Chinese electric powered motor velocity reducer is widely utilised in mining machinery, chemical business,steel metallurgy, light-weight market,environmental defense, paper creating, printing, lifting transportation, food industry and so on.

Main Series Product: R collection helical gear reducer, K collection spiral bevel equipment reducer, NGW, P sequence planetary reducer, H B sequence gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical equipment reducer, D (DBY and DCY) serial hard tooth surface cone equipment reducer, cycloid reducer, and so forth. In the meantime, map sample processing business can be undertaken.

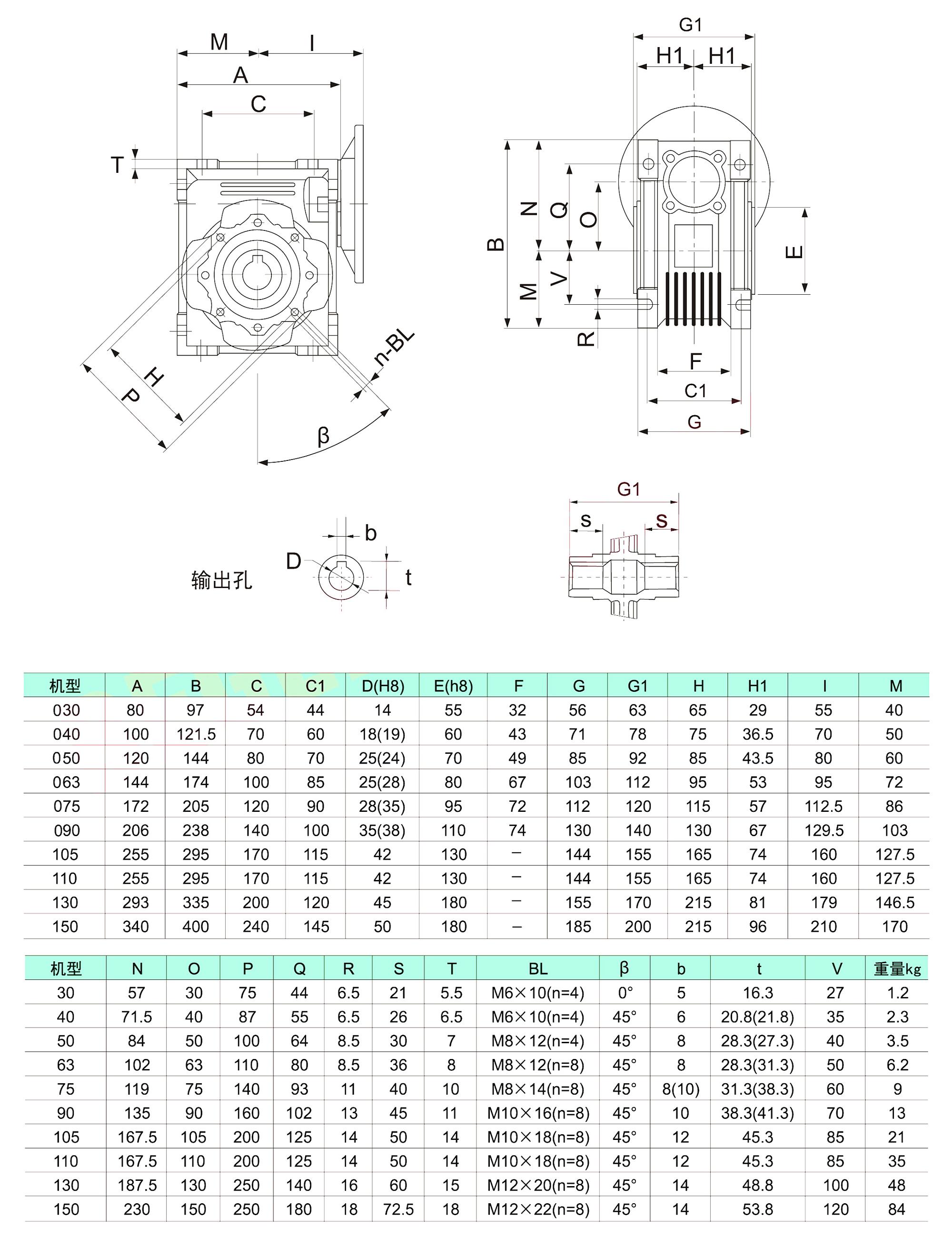

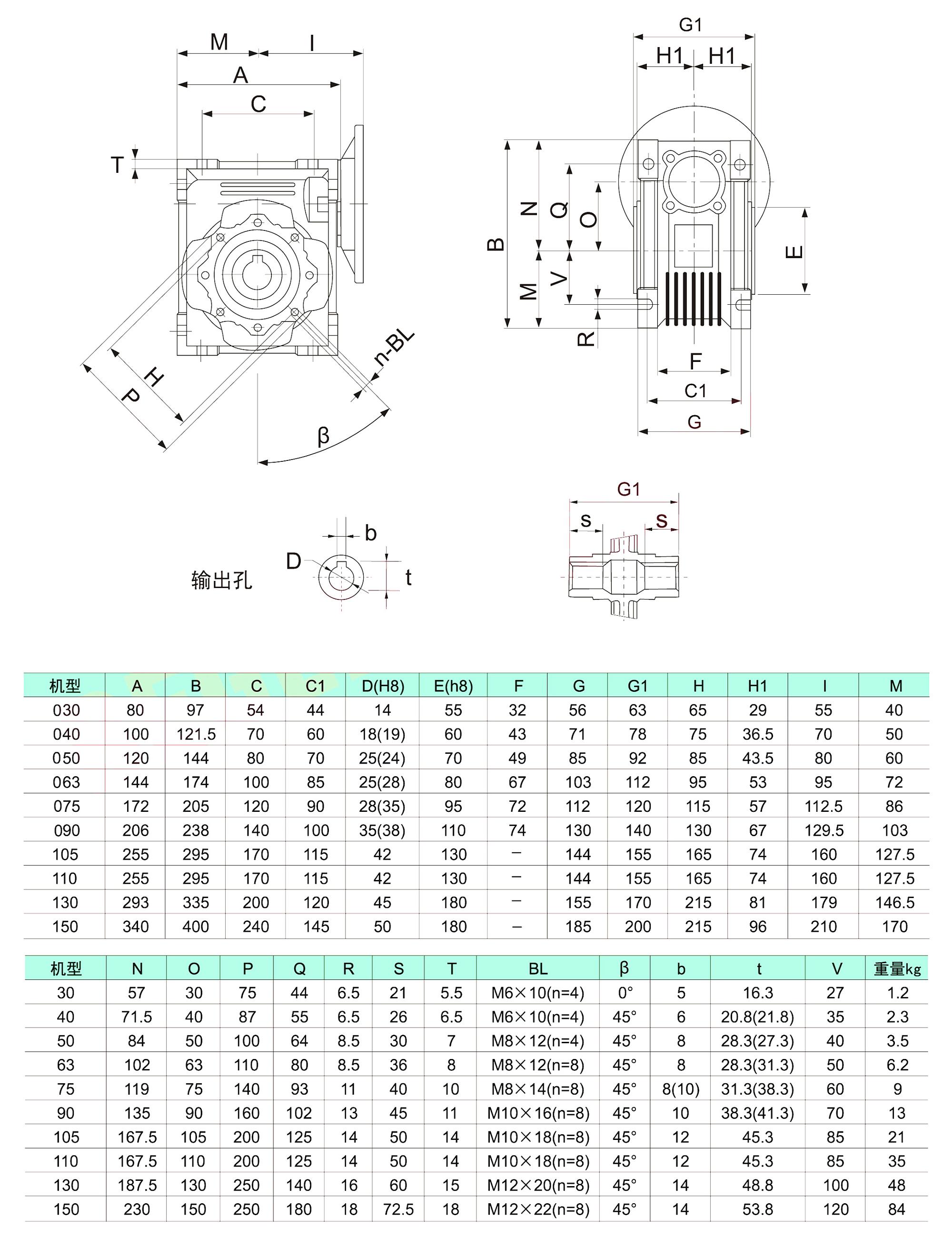

Specification

NMRV RV 90 Degree aluminium Transmission Worm Equipment Gearbox with electric powered motor:

(you should make contact with us for a lot more kinds & design)

Mounting Diamensions

Model variety for washing machine Gear Box Transmission:

Intently utilizing the perfect reduction ratio.

Reduction ratio = servo motor pace / reducer output shaft pace

Torque calculation: Torque calculation is extremely crucial for the lifestyle of reducer, and pay focus to regardless of whether the maximum torque benefit (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable energy is generally the applicable electrical power of the servo types on the industry, the applicability of the reducer is very large, the doing work coefficient can be preserved above 1.2, but the choice can also be based mostly on their very own demands to make a decision. NMRV RV 90 Degree aluminium Transmission Worm Equipment Gearbox with electrical motor.

| Driven machines | |||

| Squander water treatment method | Thickeners,filter presses,flocculation apparata,aerators,raking tools,merged longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping products, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive materials, cutter head, traversing gears |

| ChemiThe lemon tube is appropriate for transmissible electricity of sixteen-35HP, it is the preferred decision for substantial speeds and low torque transmission. The two-lobe lemon tube grants low vibrations up to 2600 rpm with lengths not exceeding 800mm. AC series with six-lobe tubes (star)cal sector | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metallic functioning mills | plate tilters, ingot pushers, winding equipment, cooling mattress transfer frames, roller straigheners, table ongoing intermittent, roller tables reversing tube mills, shears steady, casting drivers, reversing blooming mills |

| Metal functioning mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting equipment, derricking jib cranes | Cooling towers | Cooling tower followers, blowers axial and radial |

| Cane sugar creation | Cane knives, cane mills | Beet sugar manufacturing | Beet cossettes macerators, extraction crops, mechanical fridges, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper devices | Pulper drives | Cableways | Content ropeways, steady ropeway |

| Cement sector | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Technological innovation

Feature:

- 1. Big Volecity- Decreasing Ratio:Ratio of one-phase velocity-lowering is 1/11-1/87 Ratio of double phase pace-reducing is 1/112-1/5133Ratio of three-phase speed-reducing is 1/2057-1/446571more-stages can be merged in accordance to the need.

-

2. High driving effectiveness:Because of to adopting rolling engagement in slipping-in element, the driving performance can achieve above ninety%.

-

three. Small in dimension, gentle bodyweight: with compacted structure,small dimensions and light fat. Owing to adopting the principle of earth driving so that the enter and output shaft in the same axis which will built-in with the motor.

-

four. Long service daily life: Has excellent resistance to abrasion simply because the primary driving partaking parts are manufactured of bearing metal and making use of rolling friction.

-

five. Stable managing: for most driving method, we undertake multi-enamel slipping-in. Then the operating will be secure with reduced sound.

-

6. Convenient dismounting:realistic structure and style.

-

seven. Strong overloading ability,anti-compact,suited for regularly commence and double-aspect rotation.

Chinese Pace Reducer is a mechanical transmission in several fields of the countrywide economic system. The solution types protected by the market contain all sorts of equipment reducer, planetary equipment reducer and worm gearbox, as properly as a variety of specific transmission gadgets this kind of as velocity escalating system, pace management Products, including numerous types of adaptable transmission products, this kind of as compound transmission. Merchandise and solutions in the subject of metallurgy, nonferrous metals, coal, constructing resources, ships, h2o conservancy, electricity, design machinery and petrochemical industries.

In all fields of nationwide financial system and nationwide defense market, gearbox items have a wide range of aMain merchandise include: manure spreading truck, potato planting/harvesting device, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler devices, rotary tiller, rear blade, fertilizer spreader, mix rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing movie, plough suggestion and share, cultivator tine, casting components and many others.pplications. Food light sector, electrical equipment, building equipment, metallurgy machinery, cement equipment, environmental protection equipment, digital appliances, road development machinery, drinking water conservancy machinery, chemical machinery, mining machinery, conveyor equipment, building materials equipment, rubber equipment, petroleum machinery and other industries have robust need of Reducer goods. NMRV RV 030 063 Worm Equipment Reducer Gearbox with electric motor for robot arm.

Our Solutions

Packaging & Shipping

Firm Info

Established in 1995 , HangZhou Ever-Energy Machinery is a specialist producer and exporter that is concerned with the design and style, advancement and creation of Gearbox Pace Reducer. We are positioned in HangZhou of ZheJiang Province, with handy transportation entry. With our own brand “EPG”, all of our products comply with global top quality expectations and are significantly appreciated in a variety of distinct marketplaces throughout the globe.

Our company possesses full machining center, lathe, gear shaping machine, equipment milling equipment, equipment grinding device and assembling traces. Our well-equipped facilities and excellent good quality control all through all phases of creation enables us to assure overall consumer gratification.

In addition to, In 2005,we attained ISO9001 certification. As a result of our substantial good quality items and excellent customer provider, we have acquired a global product sales network reaching South The us, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other nations and areas.

With prosperous export experience, higher high quality products, competitive costs, good service and in-time shipping and delivery, we particular that we can fulfill all of your need and exceed your expectations. Our feature is vivid with new cooperative interactions with businesses from all in excess of the entire world. We seem ahead to talking with you to future discuss how we can be of services to you.

FAQ

1.Q:Are you the manufacturing unit or buying and selling business?

A:We are the specialist Manufacturing facility with over 25 a long time of expertise.

2.Q:Can you personalize according to our specifications?

A:Sure, we can design nonstandard items according to customer’s drawing and sample.

3.Q:How long is the supply day?

A:10-twenty working times.

four.Q:The place is your factory?

A:We are in HangZhou of ZheJiang Province, you can get right here by high speed train or fly to Jinan.

Welcome to visit us!