Product Description

|

CHINAMFG |

|||

|

Country of CHINAMFG |

HangZhou,China |

||

|

Type |

Engine Parts |

||

|

OEM |

VG1560080300 | ||

|

Normal or Customized |

|||

|

Package |

Plastic bag |

Front oil seal | 1 |

| VG260571208 | Flywheel gear ring | 1 | |

| AZ1242571561 | Flywheel assembly | 1 | |

| VG1246030011/12 | Connecting rod tile | 1 | |

| VG1246571034/35 | Main bearing | 1 | |

| AZ1246030007 | Connecting rod assembly | 6 | |

| VG1246030013 | Connecting rod bolt | 12 | |

| VG1246030015 | Piston assembly | 6 | |

| VG1540030005 | Piston ring | 1 | |

| VG1246030002 | Piston pin | 6 | |

| VG1246571571 | Cylinder liner | 6 | |

| D12.42-XLB | Engine repair kit | 1 | |

| VG1246040571 | Cylinder pad | 6 | |

| VG1246050571/22 | Intake and exhaust valve | 1 | |

| VG1246 0571 1 | Valve push rod | 12 | |

| VG1246 0571 1 | Valve tappet | 12 | |

| VG1246060091 | Belt | 1 | |

| VG1246060005 | Automatic tensioning wheel | 1 | |

| VG1246060094 | Pump assembly | 1 | |

| VG1246060088 | Belt | 1 | |

| VG1246060051 | Fan leaves | 1 | |

| VG1246070012 | Oil cooler core | 1 | |

| VG1246080002 | High-pressure pipeline | 1 | |

| VG1246090017 | generator | 1 | |

| VG1246090002 | starter | 1 | |

| VG124611571 | Turbocharger | 1 | |

| VG1246130008 | Air compressor | 1 | |

| VG12465716 | Fuel injector assembly | 6 | |

| WG9731471571 | Steering vane pump | 1 | |

| VG1246070031 | Oil filter | 2 | |

| VG1540080110 | Diesel filter | 1 | |

| VG | Diesel filter | 1 | |

| WG9725195712/103 | air filter | 1 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

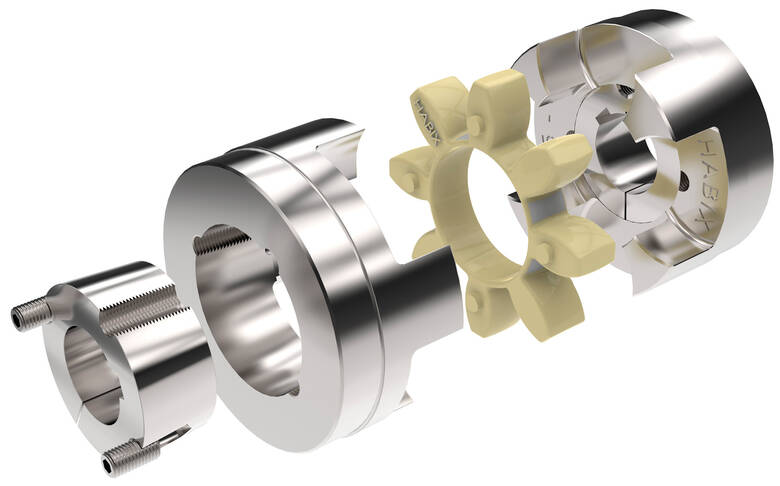

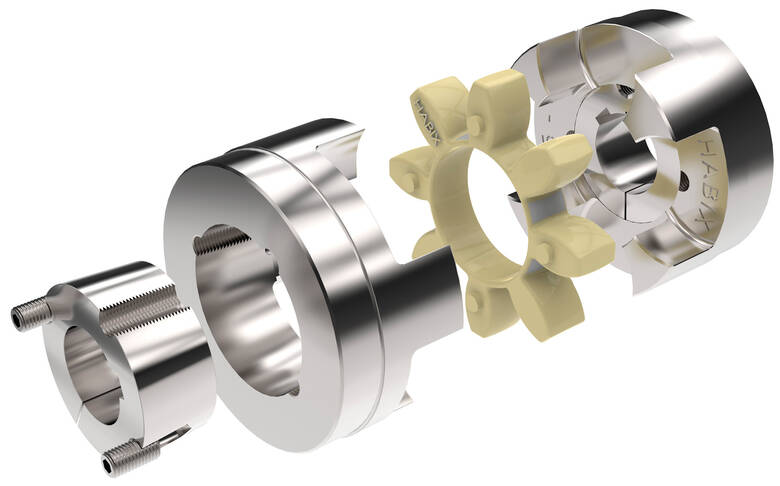

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Backlash in Elastic Couplings

Backlash refers to the amount of play or clearance between mating components in a mechanical system, particularly in elastic couplings. In an elastic coupling, backlash is the angular movement or rotation that occurs when there is a change in direction of the input shaft without an immediate response from the output shaft.

Backlash is a result of the elasticity and flexibility of the coupling’s components, such as the elastomer or other flexible elements. When the input direction changes, the elastic elements need to overcome their deformation before transmitting torque to the output shaft. This delay can lead to a temporary loss of motion and reduced precision in positioning applications.

Backlash can have a negative impact on the accuracy, repeatability, and overall performance of a machinery system. It can result in positioning errors, reduced responsiveness, and even potential damage to the system. Therefore, minimizing backlash is crucial in applications that require high precision and responsiveness.

Engineers can address backlash in elastic couplings by selecting couplings with lower compliance, optimizing the design to minimize the flexibility of the coupling elements, and using additional components like anti-backlash devices or preloaded mechanisms.

Types of Elastic Couplings for Specific Applications

There are various types of elastic couplings available, each designed to suit specific industrial applications:

- Flexible Jaw Couplings: These couplings use an elastomeric element to transmit torque and accommodate misalignment. They are commonly used in applications where shock absorption and vibration damping are important, such as pumps, compressors, and conveyor systems.

- Diaphragm Couplings: Diaphragm couplings use thin metal diaphragms to transmit torque while allowing for angular, axial, and radial misalignment. They are often used in high-performance applications where precise motion transmission is required, such as in robotics, precision machinery, and aerospace systems.

- Torsional Couplings: Torsional couplings are designed to handle high torque loads and are commonly used in heavy-duty applications, including industrial machinery, mining equipment, and large pumps.

- Disc Couplings: Disc couplings use multiple thin metal discs to transmit torque and accommodate misalignment. They are suitable for applications requiring high torque transmission and precise motion control, such as turbines, generators, and high-speed machinery.

- Beam Couplings: Beam couplings use helical cuts in a flexible beam to provide torsional flexibility and misalignment compensation. They are used in applications that require moderate torque transmission and misalignment accommodation, such as stepper motors and motion control systems.

- Oldham Couplings: Oldham couplings use three disks to transmit torque while allowing for axial misalignment. They are commonly used in applications that require accurate motion transmission, such as linear actuators and CNC machinery.

The choice of the right type of elastic coupling depends on factors such as the application’s torque requirements, speed, misalignment characteristics, and specific performance needs.

editor by CX 2024-04-24